Whether you’re a manufacturer looking for precision crafting or a hobbyist interested in woodworking, a CNC tool is a must-have to make your work easy and accurate.

New technology like CNC machining, 3D printing, and laser cutting have enabled manufacturers, designers, prototype experts, and hobbyists to produce high-precision items with less time and money.

But what is this new-age tool exactly?

CNC software provides the ability to convert digital work onto a real, physical object, automate tasks and provide a precision not seen in handwork.

It also helps to reduce material usage and production waste and improve safety while executing intricate cuts.

That’s the power of precision tools!

In this blog post, let us explore some of the best CNC software for woodworking and how you can find the one suited to your needs.

What is CNC software?

As discussed, CNC software or Computer Numerical Control (CNC) technology can convert digital work onto a 3D object.

It uses pre-programmed computer software that dictates the motion of tools and machinery.

These tools move to produce the perfect cuts to replicate the digital work.

The stronger the software and your CNC machine are, the more intricate types of cuts you can produce.

The software uses G-code, which the CNC software reads and translates into machine instructions.

You can also control the speed and direction of the machine’s movement, the depth of cuts, the precision, and more.

What to look for in Woodworking CNC software?

When selecting woodworking CNC software, it’s essential to consider several factors that will ensure the software meets your specific needs and requirements.

Let us explore what to look for in woodworking CNC software to ensure you grab the right one for your project.

Here are some common pointers; later, we will delve into specific software:

User-Friendly Interface

A user-friendly interface makes the software easy to navigate and learn, allowing you to focus on creating your designs and projects.

Look for software that offers an intuitive layout, clear icons, and helpful tooltips to guide you through the design process.

The software should also be intuitive to use, even for those who are new to CNC technology.

Many advanced tools require developer knowledge.

While these provide greater flexibility, they might not be suitable for beginners.

Compatibility With CNC Machines

The software you choose should be compatible with your CNC machine, as well as any accessories or additional hardware you may use.

This includes support for various machine controllers, spindle types, and tooling.

Ensure that the software can communicate seamlessly with your CNC machine to avoid issues during the cutting process.

Compare your CNC machine and its compatibility with various software.

There’s no point in getting software that has features your machine can’t execute.

Design Tools

Quality woodworking CNC software should offer a comprehensive set of design tools, including 2D drawing, 3D modeling, and vector editing capabilities.

These tools will enable you to create precise and intricate designs, as well as import and modify existing designs from other software or sources.

Based on the complexity of the things you want to create, find a design library and tools that suit your need.

Most software only contains the basic features for creating 3D shapes.

Material library

An ideal CNC software should include settings for a variety of materials like wood, metal, and plastic.

If not, you might have to add these settings manually, which is a time-consuming task.

A built-in material library can significantly improve your workflow by providing pre-defined settings for various types of wood and materials.

This allows you to select the appropriate cutting parameters, such as spindle speed, feed rate, and depth of cut, based on the material you’re working with, ensuring optimal cutting performance and results.

Cost

Lastly, consider the cost of the software in relation to the features it offers and your specific needs.

Some software options may provide free or low-cost licenses for personal use or hobbyists, while others may require a more significant investment of a few dollars to a few thousand dollars.

Compare the features and benefits of various software options to determine the best value for your budget and requirements.

Choose a software that fits within your budget while still providing the necessary features.

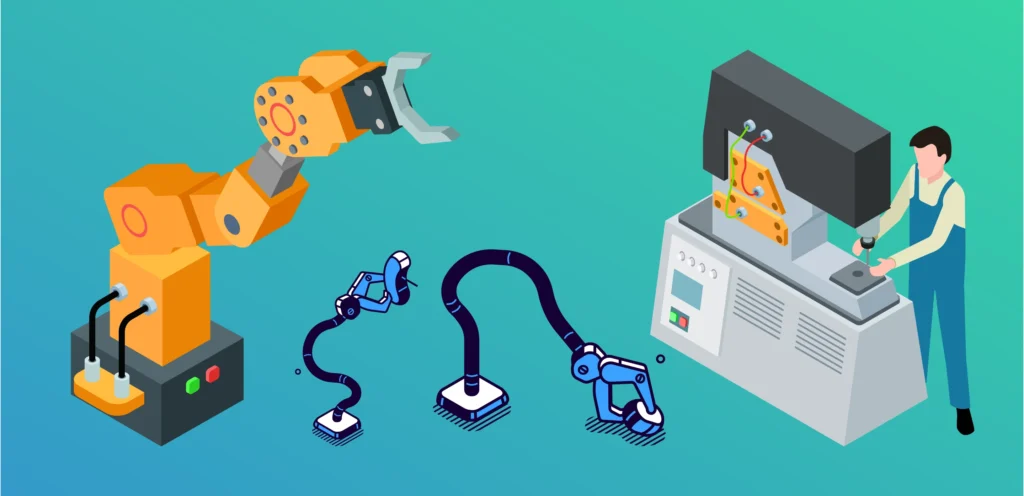

Other Tools Needed for CNC Machining

A CNC software simply dictates the commands.

To execute them, you need a CNC machine. This can be anything from a lathe cutter to a laser cutter or wood turner.

These machines, when connected to the software, will perform the necessary movements automatically.

Here’s a brief overview of some essential tools for CNC machining:

Normal Lathe Cutters

These are traditional cutting tools used in lathe machines for turning, facing, and parting operations.

Mostly used for lathing soft and semi-hard types of wood.

They are single-structured tools, typically made from high-speed steel (HSS), and are available in various shapes and sizes to suit specific machining tasks.

Carbide Welding Woodturning Tools

Primarily used for cutting and dealing with the hardwood variety.

These tools feature a carbide cutting tip welded to a steel shank, offering increased durability and cutting performance compared to HSS tools.

Carbide welding woodturning tools are ideal for roughing, finishing, and shaping operations in woodworking applications, as they maintain their sharpness longer and can withstand higher cutting forces.

Changeable Knife Wood Lathe Cutter

This type of cutter features a replaceable cutting insert or knife, allowing you to switch out the cutting edge once it becomes dull.

Uses a regular CNC blade, but it is changeable. You can clamp different blades on the cutter bar based on the material.

Changeable knife wood lathe cutters offer the advantage of reduced downtime and tooling costs, as you only need to replace the insert rather than the entire tool.

Indexable Turning Tool

Indexable turning tools are designed with a replaceable carbide insert that can be rotated or indexed to expose a new cutting edge once the current edge becomes worn.

Turning tools perform woodturning actions and can produce contours and grooves.

These tools offer increased tool life, improved productivity, and reduced tooling costs, making them popular in various machining applications, including woodworking.

Forming Turning Tool

Similar to a 3D printer, these can produce unique or irregular shapes and patterns based on your drawing.

Forming turning tools are designed to create specific shapes or profiles on a workpiece by following a pre-defined contour.

They are available in various shapes and sizes to accommodate different forming operations, such as grooving, threading, and contouring.

Forming turning tools can be made from HSS or feature carbide inserts for improved cutting performance and tool life.

5 Best CNC Software For Woodworking

If you are in a dilemma as to which CNC software is the best, the answer would probably be guided by your needs.

Let us explore the 5 best CNC software for woodworking:

1. Easel

Ξ The beginner-friendly, web-based CNC solution tailored for woodworking projects.

Easel is a popular CNC software used by hobbyists, makers, and small businesses to create designs.

It is known for its user-friendly interface and intuitive design.

Crafted especially for beginners, Easel lacks many advanced features but has everything new users might need and comes with a competitive pricing bracket.

Key Features

- User Friendly: Clean, Simple, and easily accessible features.Can automate the shortest toolpath

- Online Platform: Projects and designs are saved in a cloud platform.Supports v-carving, raster carving, and tiling

- Compatibility with Various CNC Machines: Compatible with a wide range of CNC machines.

- Design Tools: It has its own design library and a drawing board with tools to create basic shapes.

- Simulation and Preview: Allows users to preview their project as a 3D model. The preview creates the best possible toolpath.

- Settings: Has both automatic and manual cutting options. You can create rasters, grooves, ramps, and more.

PRICING PLAN

EASEL

Free to use after Easel Pro Trial.

EASEL PRO – MONTHLY

$24 + tax – Most flexible access and payment option.

EASEL PRO – YEARLY

$233 + tax (from $19.42 / month) – Most popular offering.

EASEL PRO – 3 YEAR

$599 + tax – Long-term access meets long-term value.

2. VCarve Pro

Ξ Master woodworking carving and engraving with precision and ease.

VCarve Pro is the go-to tool for routing, engraving, profiling, drilling, pocketing, and carving.

Vcarve is known for its high precision and intricate crafting while still having a relatively small learning curve.

Key Features

- Toolpath Generation: Supports various types of profiles, automates the best toolpath, and can import designs from other software.

- 3D Modelling: Supports advanced 3D modeling features such as extruding, revolving, boolean actions, and sweeping.

- Advanced machining: Supports some advanced machining options like using a rotary axis, creating double projections, spiral toolpaths, and customizing parts of a toolpath.

- Project Management: Users can organize their projects into folders, and the software includes a range of tools for creating, copying, and modifying projects.

- Customer Support: Round-the-clock advanced guidance from the support team.

- Design library: Huge clipart library, along with video tutorials.

PRICING PLAN

UNLIMITED FREE TRIAL

$699 (exclusive local taxes) – VCarve Pro gives you the power to produce complex 2D patterns with profile, pocket, drill, and inlay toolpaths, plus gives you the ability to create designs with v-carving textures as well as import and machine unlimited Vectric 3D clipart or single model files.

The ‘Pro’ edition gives you unlimited job and toolpath size, true shape nesting & job set-up sheets, ideally suited to a production environment.

3. CAMWorks

Ξ Experience streamlined CNC machining for woodworking with advanced CAD/CAM integration.

CAMWorks is a CAD-CAM tool most favored by hobbyists.

It has a range of features to produce precise machining while allowing users to automate various tasks.

It is one of the best free CNC software for woodworking, offering multiple finishes, tool and surface recognition, automatic chamfering, and more.

Key Features

- Automatic Feature Recognition (AFR): Automating the process of creating tool paths for individual features, such as pockets, holes, and slots. Also adds a chamfer by default.

- Intelligent Machining Database (IMD): This customizable database includes information such as the cutting tool, cutting speeds and feeds, and toolpath parameters.

- Automatic Toolpath Generation: Automatically generate tool paths based on the part geometry and the defined machining parameters.

- Advanced Milling and Turning Strategies: Involves advanced milling and turning strategies such as 3D milling, high-speed machining, tapered points, and multi-axis machining.

- Integrated Solid Works Interface: This makes it easier to transfer data directly from SolidWorks.

PRICING PLAN

CUSTOM QUOTE

CAMWorks has not provided pricing information for their service. This is common practice for software sellers and service providers. Contact CAMWorks to obtain current pricing.

4. Fusion360

Ξ All-in-one cloud-based CAD/CAM for innovative woodworking designs.

Fusion 360 by Autodesk is perhaps one of the most well-known 3D modeling software that doubles as a CNC tool.

It has the most advanced modeling interface that includes parametric modeling and can be used for practically anything from manufacturing to animated model creation.

These features make Fusion 360 an all-in-one solution for design, engineering, and manufacturing. But let’s take a look at its CNC features:

Key Features

- Automated toolpaths: Fusion 360 claims to create toolpaths 50% faster than its competitors, which reduces 60% of overall machining time.

- Collaborative Design: Enables collaboration between designers, engineers, and other stakeholders. All files are managed under a single AutoDesk account which means you can also import any CAD files directly.

- Machining: Can perform up to 5-axis machining, turning, milling, and carving. Also includes simulation tools to enable users to test and validate their designs.

- Additive Manufacturing: Allows 3D printing and laser cutting file creation.

PRICING PLAN

OPTION #1

$56/paid monthly

OPTION #2

$436/paid annually – Savings of 35% compared to the monthly price

OPTION #3

$1,635/paid every 3 years – Best Value

5. Aspire

Ξ Bring your woodworking ideas to life with powerful 3D modeling and sculpting capabilities.

Aspire, developed by Vectric, is a versatile CNC software that builds upon the capabilities of VCarve Pro by offering full 3D modeling and sculpting tools for creating intricate woodworking designs.

With its extensive toolset, including 2D drawing, editing tools, and advanced toolpath strategies, Aspire caters to users looking for a more comprehensive solution for their woodworking projects.

Key Features

- Developed by Vectric, the creators of VCarve Pro

- Full 3D modeling and sculpting tools for intricate designs

- 2D drawing and editing tools for creating vector shapes

- Toolpath strategies for 3D machining, including roughing and finishing

- Support for importing 3D models from other software (STL, OBJ, SKP, etc.)

PRICING PLAN

UNLIMITED FREE TRIAL

$1,995 (exclusive local taxes) – Aspire provides a powerful but intuitive software solution for creating and cutting parts on a CNC router. There are tools for 2D design and calculation of 2D toolpaths such as Profiling, Pocketing, and Drilling as well as 2.5D toolpaths including; V-Carving, Prism carving, Moulding Toolpaths, Fluting, The Chamfer Toolpath, and even decorative texturing strategy.

What makes Aspire our premium package is the added 3D design tools which enable you to create your own 3D relief models and machine them with 3D machining strategies.

6. Mastercam

Ξ Achieve professional-grade precision and control in your woodworking CNC operations.

Mastercam is a widely used and powerful CNC software with advanced design and machining features, suitable for various industries, including woodworking.

Its comprehensive 2D and 3D CAD/CAM tools, multi-axis machining capabilities, and integration with popular CAD software make Mastercam a preferred choice among professional users looking for a high level of control and customization in their CNC machining process.

Key Features

- Widely used CNC software with advanced design and machining features

- Comprehensive 2D and 3D CAD/CAM tools for design and machining

- Advanced toolpath strategies for efficient cutting and material removal

- Support for multi-axis machining and automation

- Integration with popular CAD software, such as SolidWorks and Autodesk Inventor

PRICING PLAN

CUSTOM LICENSING OPTIONS

MasterCAM has flexible licensing options available to ensure we have access to the best performance, productivity, and partnership with respect to our business needs.

Subscription License

Subscription licensing offers a lower upfront cost. It is renting a license for a term versus paying for a perpetual license outright. This provides flexibility with lower, predictable payments to access the productivity benefits of Mastercam’s industry-leading CAD/CAM software. You also receive the benefits of exclusive Mastercam University content and access to the Mastercam Tech Exchange.

Perpetual License

A perpetual license to operate Mastercam offers a lower price over time. This is a software license to operate Mastercam, paired with Mastercam Maintenance to give you the ability to upgrade to the latest version of Mastercam for the duration of the Maintenance term. This provides cost savings for users with long-term planning and budgeting capabilities.

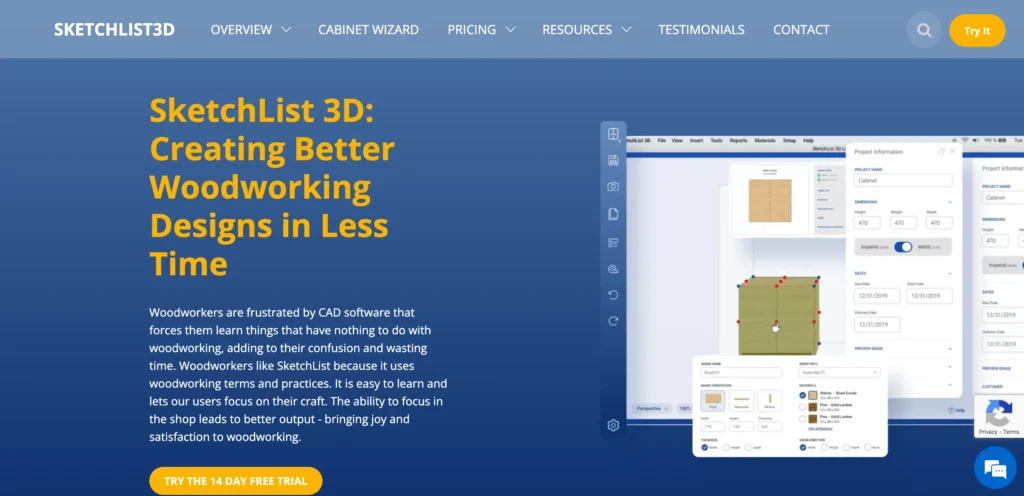

7. SketchList 3D V5 PRO

Ξ The ultimate 3D planning and design tool for woodworking and cabinetry.

SketchList 3D V5 PRO is a woodworking and cabinetry design software that simplifies the design process with its intuitive 3D interface and built-in material and hardware libraries.

Designed to streamline project planning and execution, SketchList 3D generates essential documents such as cut lists, shop drawings, and material reports, making it a valuable tool for woodworking professionals and enthusiasts alike.

It is a potent software tool designed for efficiency and accuracy.

However, its main attraction is that it can also produce 5 special types of woodworking joints and multiple groove profiles!

Key Features

- 3D Design: Well-developed 3D design tool and inbuilt library. Can produce complex 3D shapes, along with rendering and 4-side view simulations.

- Custom Material Layouts: Import material catalogs and customize material layouts.

- Cut List Generation: Offers a clear and concise list of essential materials and parts with preset cut list specifications. Supports 10 different wood grain types.

- Machining: Apart from the usual machining and milling, it provides users with a range of joinery options, contouring profiles,

- Other features: Allows users to generate a purchase report of the material amount needed, export part data into Excel, and automate the optimization of print parts to save materials.

PRICING PLAN

SketchList 3D V5 Hobby

– $200 – One-Time Purchase

SketchList 3D Hobby is perfect for the casual user of woodworking design software. All design capabilities found in SketchList 3D Pro are included in this version. Note that there are limitations to the number of features and reports Hobby users can access.

– $39/month – Monthly SubscriptionSketchList 3D V5 Pro

– $850 – One-Time Purchase

SketchList 3D Pro is designed for professional woodworkers, woodcraft businesses, and high-end home craftsmen and women. Its advanced features, utilities, and capabilities will save you time, reduce expenses, and make you much more productive overall. Use the reports, lists, spreadsheets, and 3D renderings to generate proposals to assist you in selling your work.

– $79/month – Monthly Subscription

Tips for Maximizing the Potential of Your CNC Software

To get the most out of your chosen CNC software, consider the following tips:

- Regular software updates: Keep your software up-to-date to take advantage of new features, bug fixes, and performance improvements.

- Optimal machine settings: Spend time learning the optimal settings for your CNC machine, such as spindle speed, feed rate, and depth of cut, to ensure efficient and accurate cutting.

- Proper maintenance of CNC machines: Regularly clean and maintain your CNC machine to ensure its longevity and reliability.

- Seeking expert advice and training: Participate in online forums, webinars, and workshops to learn from other experienced users and experts in the field. This will help you stay up-to-date with industry trends and best practices.

Conclusion

In conclusion, finding the best CNC software for woodworking depends on your specific needs, skill level, and budget.

With a diverse range of options available, such as Easel for beginners, VCarve Pro and Aspire for carving and engraving enthusiasts, and Fusion 360 for a comprehensive, cloud-based CAD/CAM solution, there is a CNC software to suit every woodworking application.

CNC tools have made it possible to create industry-level precision-finished items within the comfort of our own homes (or garages – the machines are BIG!).

Though CNC machining is a bit more expensive than conventional machine-based woodworking, yet it allows one to create accurate prototypes and reduce material wastage to a great extent.

As technology advances, CNC software will likely continue to play a crucial role in the manufacturing industry for years to come.

By carefully considering the pros and cons of each option and evaluating their features, you can select the perfect software to help you bring your woodworking projects to life.

Embrace the world of CNC machining and unlock new possibilities for creativity, precision, and innovation in your woodworking journey.

Get a heads up and start exploring these tools today!